The warmth sources ordinarily utilized for soldering are the electric soldering iron and the gas blowlamp. The previously well-known customary fire warmed soldering iron is currently infrequently utilized. When choosing which instrument to utilize you ought to recall that it is an exercise in futility attempting to solder with a device that is not incredible enough for the work. Similarly well, one which is too amazing may warm up the solder excessively and debilitate the joint. For exceptionally sensitive work, you will in all probability have to utilize an electric soldering iron. A few gas blowlamps can do this work well as well. For greater electrical positions and for soldering adornments and model-production, you can utilize a blowlamp which takes a fine or additional fine burner a fire which is very hot however not very large or diffuse is required or one of the more impressive soldering irons.

The temperature the solder and joint need to arrive at standard solder melts at about 250°C, and this temperature should be kept up in the joint constantly it is being made. The warm size of the joint and its quick environmental factors – an enormous joint will require a bigger wellspring of warmth to empower it to arrive at the necessary temperature, and when soldering metals, like copper, which are excellent conveyors of warmth, a consistent inventory of warmth is expected to keep the temperature high. The situation of the joint if the joint is close to temperature-delicate electronic parts like semiconductors, it is savvy to embed a warmth sink between the joint and the segment to clean up the warmth utilized in soldering to keep it from voyaging. A mass of metal is the standard warmth sink, and substantial pair of pincers will frequently get the job done On the other hand, if the joint has an enormous surface region and is presented to the air, it might emanate the warmth away excessively fast.

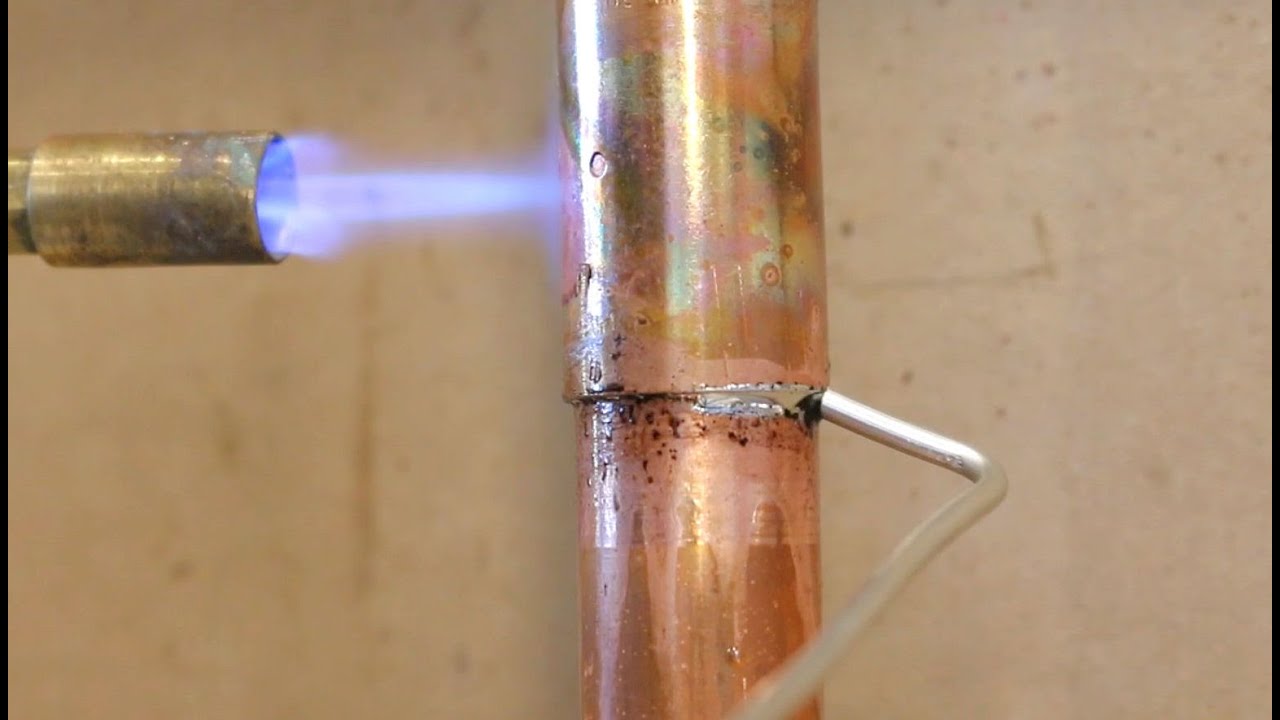

This can be overwhelmed by encasing the joint in an impermanent block hearth, or by covering part of it in a bed of cinders. how to solder copper pipe Brazing utilizes composites of copper and zinc which soften at a lot higher temperatures than solder 700 to 800°C and give more grounded joints. An extraordinary transition or a borax paste is required. Braze or bronze welding utilizes a similar kind of composite, however as opposed to running it into the joint a filet is developed on a superficial level. In the event that the joint is little, it very well might be feasible to arrive at the temperature needed with a gas blowlamp, by playing the fire straightforwardly on the joint. On the off chance that this is not effective, an all the more remarkable warmth source is required. A brazing connection is accessible for use with a curve welder. This normally appears as two carbon bars fixed in a hand-held clasp. This source is both amazing and wild, so it is prudent to rehearse this strategy prior to endeavoring to utilize it for fix.